Many technologies can be used to improve the management of waste in the oilfield. One of these technologies may include sensors that are attached directly to trash cans. These sensors aid front-load and rolling-off haulers with managing their container inventory as well as routes. The sensors will also allow them to plan their routes and give jobs more evenly among their drivers. Compology was the first to develop this technology. Its sensors can monitor the tilt of a container, which helps them better manage their inventory.

Smart waste management

Smart waste management technologies are changing the way we manage our waste. Sensors mounted on trash cans to monitor the level of waste and notify collection agencies when a container becomes full. Advanced optical sorters and disk screen technology make sorting fast and easy. Natural gas is now the preferred choice for garbage trucks. It is quieter, more fuel-efficient, and is also quieter. Apps for mobile devices help simplify the waste management process.

Sensors in dumpsters

Waste management companies can monitor the condition of their dumpsters using sensors. Waste management companies can adjust pickup and delivery times for each dumpster by using data from sensors. Furthermore, machine learning can help them sort waste according to its type.

Recycling apps

Recycling apps are a great way for individuals to recycle easily. You can search for local recycling centres and sort recyclable materials by type. This makes it easy to keep track of when to recycle and how much it will cost. They also offer users the latest news and insights in the waste and recycling sector.

Oil field waste management

Diverse techniques are employed to reduce the pollution and decrease the waste volume in oil fields. These technologies can be used for any type of oil or gas waste. Superfund liability laws have increased the importance of oil-and gas waste recycling. While some technologies may be more effective than others depending on how they are managed, top management support is crucial. This includes a thorough inventory and classification of waste streams as well as the ability to adapt to site-specific variations.

Autoclave sterilization technology

An autoclave sterilization system can be an effective tool in waste management. The sterilization process involves the removal and subsequent use of high-pressure steam in order to kill pathogens. This method is very effective in eliminating a wide range of pathogens including prions. It does not require hazardous chemicals. These autoclaves are available in many sizes and can accommodate a variety of medical waste. Temperatures range between 250 to 300 F.

Bin-E

Bin-E technology is an AI-based system that recognizes objects and automatically detects waste to optimize waste management. It's accurate and cost-effective. Its automated recognition and segregation processes eliminate the need for manual sorting and waste collection.

FAQ

Which kind of people use Six Sigma

People who have worked with statistics and operations research will usually be familiar with the concepts behind six sigma. But anyone can benefit from it.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

What are the four major functions of Management?

Management is responsible of planning, organizing, leading, and controlling people as well as resources. It also includes developing policies and procedures and setting goals.

Management helps an organization achieve its objectives by providing direction, coordination, control, leadership, motivation, supervision, training, and evaluation.

The following are the four core functions of management

Planning - This is the process of deciding what should be done.

Organizing - Organizing involves deciding how things should be done.

Directing – This means to get people to follow directions.

Controlling – Controlling is the process of ensuring that tasks are completed according to plan.

What does Six Sigma mean?

Six Sigma employs statistical analysis to identify problems, measure them and analyze root causes. Six Sigma also uses experience to correct problems.

The first step is identifying the problem.

Next, data are collected and analyzed in order to identify patterns and trends.

Then, corrective actions can be taken to resolve the problem.

Finally, the data are reanalyzed in order to determine if it has been resolved.

This cycle will continue until the problem is solved.

What is TQM and how can it help you?

When manufacturing companies realized that price was not enough to compete, the industrial revolution brought about the quality movement. They had to improve efficiency and quality if they were to remain competitive.

In response to this need for improvement, management developed Total Quality Management (TQM), which focused on improving all aspects of an organization's performance. It included continuous improvement, employee involvement and customer satisfaction.

Statistics

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

External Links

How To

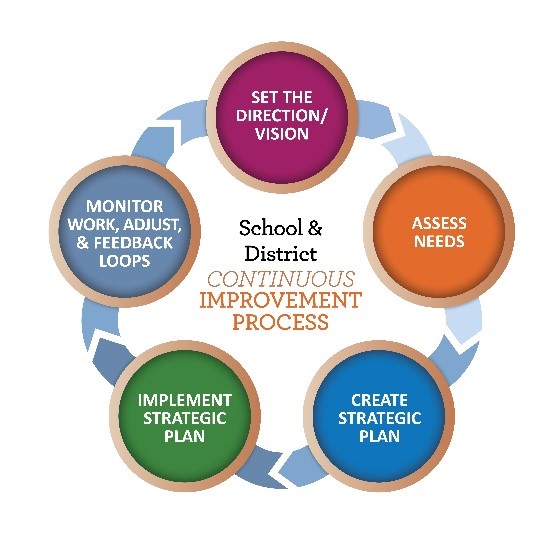

How can you implement a Quality Management Plan?

QMP, which was introduced by ISO 9001:2008, is a systematic approach to improving products, services, and processes through continuous improvement. It helps to improve customer satisfaction and product/service quality by continuously measuring, analyzing, controlling and improving.

QMP is a common method to ensure business performance. QMP is a standard method that improves the production process, service delivery, customer relationship, and overall business performance. QMPs should cover all three dimensions - Products, Processes, and Services. If the QMP only covers one aspect, it's called a "Process QMP". The QMP that focuses on a Product/Service is called a "Product." QMP. The QMP that focuses on customer relationships is known as the "Customer" QMP.

Scope, Strategy and the Implementation of a QMP are the two major elements. They are defined as follows:

Scope: This determines the scope and duration of the QMP. This scope can be used to determine activities for the first six-months of implementation of a QMP in your company.

Strategy: These are the steps taken in order to reach the goals listed in the scope.

A typical QMP is composed of five phases: Planning Design, Development, Implementation and Maintenance. Each phase is explained below:

Planning: This stage is where the QMP objectives are identified and prioritized. All stakeholders involved in the project are consulted to understand their requirements and expectations. The next step is to create the strategy for achieving those objectives.

Design: This stage involves the creation of the vision, mission, strategies and tactics necessary to implement the QMP successfully. These strategies are put into action by developing detailed plans and procedures.

Development: The development team is responsible for building the resources and capabilities necessary to implement the QMP effectively.

Implementation: This involves the actual implementation of the QMP using the planned strategies.

Maintenance: It is an ongoing process that maintains the QMP over time.

Several additional items should be added to the QMP.

Stakeholder Involvement: Stakeholders are important for the success of the QMP. They should be involved in planning, design, development and implementation of the QMP.

Project Initiation - A clear understanding of the problem statement, and the solution is necessary for any project to be initiated. The initiator must know the reason they are doing something and the expected outcome.

Time frame: It is crucial to know the time frame for the QMP. For a short time, you can start with the simple version of the QMP. If you're looking to implement the QMP over a longer period of time, you may need more detailed versions.

Cost Estimation - Cost estimation is an important part of the QMP. You cannot plan without knowing how much money you will spend. Before you start the QMP, it is important to estimate your costs.

The most important thing about a QMP is that it is not just a document but also a living document. It changes as the company grows. So, it should be reviewed periodically to make sure that it still meets the needs of the organization.