The process of industrial waste management involves the collection, transporting, and proper disposal of hazardous waste. In order to prevent contamination of the surrounding area, hazardous waste must be disposed of in a modern secure facility. This costly process involves the preparation and transport of large quantities of waste. On-site remediation is another option. It involves construction of a new facility at an existing location and treatment for water pollution. Some plants use full containment. This involves the removal of groundwater flow from the area and capping it.

Construction and demolition debris

Construction and demolition debris is an industrial waste generated during construction. The majority of construction waste can legally be disposed in landfills. However, in some locations, this waste is illegally dumped on land or in water bodies. Furthermore, it can be hazardous for the environment and against regulations protecting commerce or human health. The United States alone sees millions of tons annually of building-related rubbish being dumped in landfills every year. Therefore, strict regulations must be followed when managing construction waste.

Manufacturing waste

A circular economy is all about managing manufacturing waste. In recent years, the use of recycled materials has increased significantly, as are the amount of energy and materials saved. Manufacturers have a wide range of options today to recycle and manage their waste. Some technologies allow manufacturers to reduce their production costs and increase their profits.

Agriculture waste

Agriculture waste refers to solid wastes from farming operations. It includes animal production, crop production, food processing, and other agricultural wastes. These solid wastes include animal carcasses and waste from animal feeding, feathers and hoofs, as well as crop residues.

Chemical waste

The majority of chemical waste is hazardous, meaning that it poses a risk to human health or the environment. There are regulations in place that can help you safely dispose of hazardous materials. Additionally, improper disposal of hazardous wastes can result in severe environmental penalties. However, some types of waste are not considered hazardous and, thus, are not subject to the same regulations.

Mining waste

The mining industry produces huge amounts of waste. Mining owners need to know how to properly dispose of this waste. Erich Lawson is a freelance writer and a passionate environmentalist. He is a freelance writer and a passionate environmentalist. He enjoys helping businesses cut their garbage costs while increasing revenue by recycling.

Oil & Gas Waste

For oil and gas wastes, there are specific requirements for industrial waste management. Drilling wastes, production fluids and produced waters are the most common types. To minimize the impact of these wastes on the environment, they should be properly disposed off.

Radioactive waste

It is important to properly dispose of solid waste for public health and the environmental quality. A waste with a short life span (less than 100-years) can be safely disposed off in specially designed engineering modules. These include reinforced concrete trenches or tile holes. Near Surface Disposal Facility or NSDF is constructed below the ground. Here, the waste can be buried upto 500 metres below ground. These facilities are equipped with multi-barrier systems to prevent the spread of radioactive waste.

Others

Global industrial waste management market is highly fragmented with many international and local players. Industry leaders are focused on product innovations in waste management. Industrial waste management is comprised of solid, fluid, and gaseous materials generated in various industrial industries. These materials can be hazardous or non-hazardous. Many of these materials can be disposed of in a landfill or incinerated. These practices can lead to significant environmental and wildlife damage.

FAQ

What is the difference between management and leadership?

Leadership is about influence. Management is all about controlling others.

Leaders inspire others, managers direct them.

Leaders inspire people to achieve success. Managers keep their workers focused.

A leader develops people; a manager manages people.

What is TQM exactly?

When manufacturing companies realized that price was not enough to compete, the industrial revolution brought about the quality movement. They needed to improve quality and efficiency if they were going to remain competitive.

Management realized the need to improve and created Total Quality Management, which focused on improving all aspects within an organization's performance. It included continuous improvement processes, employee involvement, and customer satisfaction.

What is Six Sigma?

It's an approach to quality improvement that emphasizes customer service and continuous learning. It is a method that eliminates defects using statistical techniques.

Motorola invented Six Sigma in 1986 as part its efforts to improve manufacturing.

It was quickly adopted by the industry and many companies are now using six-sigma to improve product design, production, delivery, customer service, and product design.

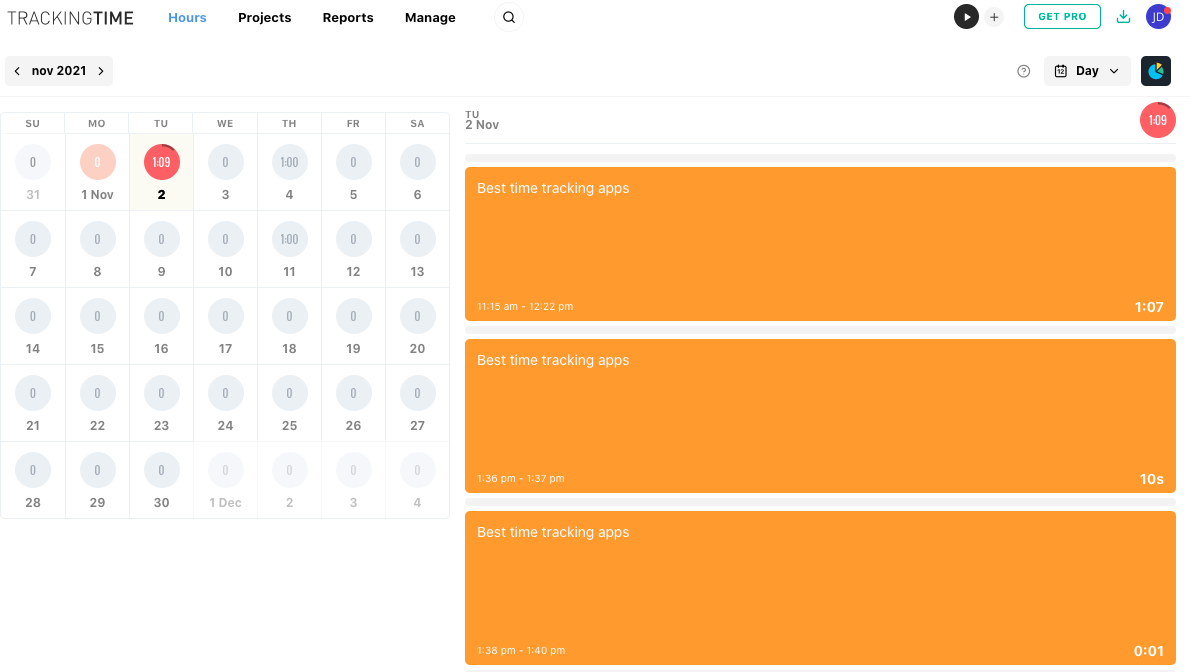

Why is it important that companies use project management methods?

Project management techniques are used in order to ensure projects run smoothly, and that deadlines are met.

This is because many businesses depend heavily upon project work to produce products and services.

These projects are essential for companies.

Companies could lose their time, reputation, and money without effective project management.

How can a manager motivate his/her staff?

Motivation can be defined as the desire to achieve success.

You can get motivated by doing something enjoyable.

You can also get motivated by seeing your contribution to the success or the improvement of the organization.

For example, if you want to become a doctor, you'll probably find it more motivating to see patients than to study medicine books all day.

Another source of motivation is within.

One example is a strong sense that you are responsible for helping others.

Maybe you like working hard.

Ask yourself why you feel so motivated.

Then try to think about ways to change your situation to be more motivated.

Statistics

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

External Links

How To

How can you create a Quality Management Plan, (QMP)?

QMP (Quality Management Plan), introduced in ISO 9001,2008, provides a systematic method for improving processes, products, or services through continuous improvement. It is about how to continually measure, analyze, control, improve, and maintain customer satisfaction.

QMP is a common method to ensure business performance. QMP's goal is to improve service delivery and production. QMPs should address all three dimensions: Products, Services, and processes. If the QMP only covers one aspect, it's called a "Process QMP". The QMP that focuses on a Product/Service is called a "Product." QMP. QMP stands for Customer Relationships.

Two main elements are required for the implementation of a QMP. They are Scope and Strategy. They can be described as follows:

Scope is what the QMP covers and how long it will last. For example, if your organization wants to implement a QMP for six months, this scope will define the activities performed during the first six months.

Strategy: This describes the steps taken towards achieving the goals set forth in the scope.

A typical QMP is composed of five phases: Planning Design, Development, Implementation and Maintenance. Each phase is explained below:

Planning: This stage determines the QMP goals and prioritizes them. In order to fully understand and meet the needs of all stakeholders involved in this project, they are consulted. Once the objectives and priorities have been identified, it is time to plan the strategy to achieve them.

Design: During this stage, the design team develops the vision, mission, strategies, and tactics required for the successful implementation of the QMP. These strategies are implemented by the development of detailed plans and procedures.

Development: Here, the development team works towards building the necessary capabilities and resources to support the implementation of the QMP successfully.

Implementation is the actual implementation of QMP according to the plans.

Maintenance: Maintaining the QMP over time is an ongoing effort.

Additionally, the QMP should include additional items:

Stakeholder Engagement: It is crucial for the QMP to be a success. They must be involved in all phases of the QMP's development, planning, execution, maintenance, and design.

Project Initiation. It is important to understand the problem and the solution in order to initiate any project. The initiator must know the reason they are doing something and the expected outcome.

Time Frame: This is a critical aspect of the QMP. If you plan to implement the QMP for a short period, you can start with a simple version. However, if you have a long-term commitment, you may require more elaborate versions.

Cost Estimation - Cost estimation is an important part of the QMP. Planning is not possible without knowing the amount of money you will spend. Therefore, cost estimation is essential before starting the QMP.

QMPs should not be considered a static document. It changes with the company. It should therefore be reviewed frequently to ensure that the organization's needs are met.