Certification in supply chain management has many benefits. Having this designation demonstrates that you are an expert in your field and can be considered for promotion within your current company or a new position. Some supply chain certifications can be obtained for free, while others require payment upfront. Some companies will reimburse the amount within 30 business days. Others may charge you the fee directly to your company card. Which supply-chain certification is right? Here are some tips to help guide you in your decision-making process.

CSCP

Obtaining the CSCP certification will help you differentiate yourself from other professionals in the supply chain industry. This credential will help you prove your knowledge in the supply chain, and it will make your organization a valuable asset. It will also allow you to be competitive in today's market. This certification will help you increase your earning potential and improve your career prospects. APICS CSCP offers a range of learning options, including both an instructor-led and online course. This course will show you how to increase profitability and productivity within supply chains.

This course will provide an overview of the key concepts and components of supply chains. These concepts include market segmentation. Demand planning. Customer relationships. Globalization. Influence on demand. Inventory planning. Students will also be taught market research and sustainability. Candidates can sit for the CSCP exam once they have completed the course. The minimum experience required to obtain this certification is three years in supply chain management.

CPSM

For professionals working in the global supply-chain, the CPSM supply certification is a great credential. It provides a common language, terminology and ideas among supply chain professionals. The extensive ISM materials can be used to prepare for the certification. David Panzera took the exam after having studied for five years by himself. He says the course has helped him develop his skills in a new way. The different courses and study material available for this certification are listed below.

You will need to have three- to five years of supply management experience to become a CPSM. The program is divided in three modules. Each module focuses specifically on one aspect of supply-management. You must be able to apply your knowledge to real-world situations in order to pass the exam. Depending upon your study schedule, the CPSM supply chain certification program can be completed within six to twelve weeks. It is important that you recertify each three years in order to maintain this credential.

SCPro

There are three levels of SCPro Certification. The first requires a bachelor’s degree in supply-chain management. The second, and third, require at least seven year supply chain experience. Level 1 exam has 160 multiple-choice items. It is divided into 8 sections. A candidate must also have experience in the analysis business cases and case studies.

The Bridge Exam, in addition to standard SCPro certifications, allows candidates to draw on their professional experience and gain a higher-level credential. Candidates must hold a supply-chain-related advanced degree or at least four years' work experience to be eligible for Bridge Exam. For the Level One exam, candidates must have at least four years of experience in supply chain management. The Bridge Exam can be completed in as little as 90 minutes. The Bridge Exam is available online.

CPSD

To demonstrate your skills and knowledge in supply management, if you have a background you can take the CPSD Supply Chain Certification Exam. This exam will test your knowledge in three areas: supplier management, financial management and supplier relationship management. Additional knowledge will include organizational global strategy and procurement. The first step to CPSD certification is the Supply Management Core exam, which consists of 180 questions that must be answered in three hours. The next two exams, Leadership and Transformation in Supply Management, and Supply Management Integration, each consist of 165 questions.

The CPSM certification program consists of five modules and three exams. These modules cover the most important areas of production management and inventory management. There are three exams in the CPSM certification program, and you can take them in any order. You can also waive the CPSD exams if you have completed the CPSM certification. Both exams last 180 minutes and have 180 questions. CPSM, CPSD and CPSM certifications are valid up to three years. Although the CPSM exam can be more challenging than the CPSD exam it is still worth the investment if you are interested in learning more about the program and being more efficient.

FAQ

What kind of people use Six Sigma?

Six Sigma is well-known to those who have worked in operations research and statistics. Anybody involved in any aspect or business can benefit.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

Six Sigma is so popular.

Six Sigma is easy to implement and can produce significant results. Six Sigma also gives companies a framework for measuring improvement and helps them focus on what is most important.

How can a manager motivate his/her staff?

Motivation is the desire to do well.

Engaging in something fun can be a great way to get motivated.

Another way to get motivated is to see yourself as a contributor to the success of the company.

For example: If you want to be a doctor, you might find it more motivating seeing patients than reading medical books all day.

A different type of motivation comes directly from the inside.

Perhaps you have a strong sense to give back, for example.

Maybe you like working hard.

Ask yourself why you aren't feeling motivated.

Then, consider ways you could improve your motivation.

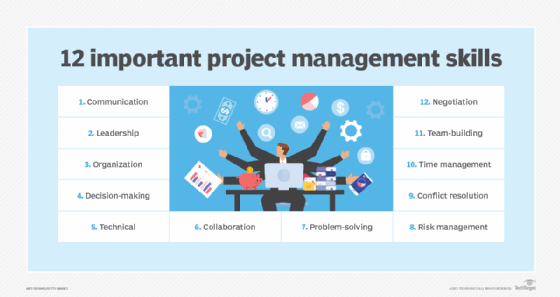

Why is it so important for companies that they use project management techniques

Project management techniques are used to ensure that projects run smoothly and meet deadlines.

This is due to the fact that most businesses rely heavily upon project work in order to produce goods, and services.

These projects are essential for companies.

Companies can lose time, money, and reputation if they don't have a good project management system.

What is the difference between management and leadership?

Leadership is about inspiring others. Management is about controlling others.

Leaders inspire others, managers direct them.

A leader inspires others to succeed, while a manager helps workers stay on task.

A leader develops people; a manager manages people.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. They were developed in Japan by Toyota Motor Corporation (in the 1980s). It was designed to produce high-quality products at lower prices while maintaining their quality. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement refers to continuously improving existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. To achieve the best results, these five elements must be used together.

Lean Production System

Six key concepts make up the lean manufacturing system.

-

Flow - focuses on moving information and materials as close to customers as possible.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban - use visual signals such as colored tape, stickers, or other visual cues to keep track of inventory;

-

Theory of constraints: Identify bottlenecks and use lean tools such as kanban boards to eliminate them.

-

Just-intime - Order components and materials at your location right on the spot.

-

Continuous improvement is making incremental improvements to your process, rather than trying to overhaul it all at once.